Thanks to everyone’s continuous involvement in our LEAN initiative, we have submitted over 600 ideas so far this year, saving more than $200,000! These numbers are proof of the positive … Read More

Measuring Success in a LEAN Environment

One of the key elements of a successful LEAN initiative is properly measuring the process. In simple terms, if you treasure it, measure it. This can apply to anything your … Read More

LEAN: Collaborative Learning and Sharing Experiences with 5 Key Groups

There are many reasons companies call their experience with LEAN “a journey.” Each company finds their own unique approach and path to reducing waste and creating value in their organization. … Read More

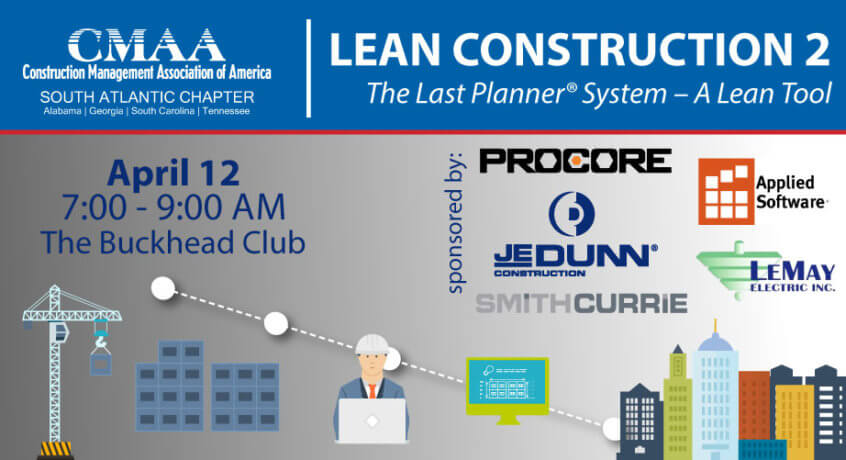

Bryan Decker a Panelist at CMAA-SAC’s Upcoming Lean Construction Breakfast

Our very own Bryan Decker will be joining fellow industry experts for the Lean Construction 2 Breakfast Meeting on April 12. This panel discussion, hosted by Construction Management Association of … Read More

8 Wastes of LEAN

To help everyone keep thinking LEAN, we are examining the 8 Wastes of LEAN and what we can do to help eliminate them from our daily routines.

Using Safety Metrics to Identify Opportunities for LEAN

Injuries, unsafe actions and dangerous conditions are always a top concern for McKenney’s. However, they are not just safety related. They are often indicators of inefficiency and waste in our … Read More

Bottlenecks: Identifying What’s Slowing Down a Process

Have you ever worked on a project that was moving along well when—seemingly out of the blue—you started seeing delays and your stress levels went up? This may have been … Read More

5S of LEAN

As we continue our LEAN initiative at McKenney’s, we are utilizing more tools and methods to make an impact across our campuses. One way we’re doing this is by implementing … Read More

LEAN at McKenney’s

At McKenney’s, we are committed to doing everything we can to improve both the quality of our services to our customers and our employees’ quality of life, and we are … Read More