Certain rooms in a healthcare building should be correctly pressurized with respect to surrounding areas. If rooms are not properly pressurized, an imbalance may exist between the supply and exhaust rates for the room. The following are examples of positively pressurized rooms:

Certain rooms in a healthcare building should be correctly pressurized with respect to surrounding areas. If rooms are not properly pressurized, an imbalance may exist between the supply and exhaust rates for the room. The following are examples of positively pressurized rooms:

- Operating Rooms

- Delivery Rooms

- Trauma Rooms

- Laser Eye Rooms

- Pharmacy

- Surgical Supply Clean Workrooms and Sterile Storage

McKenney’s engineers collaborate to offer the their expert knowledge on ASHRAE 170 Room Pressurization.

- What is room pressurization?

- How do we determine and set room pressurization?

- What types of rooms require pressurization?

Definitions of terms used throughout this blog:

- Protective Environment (PE) Room:

Defined by ASHRAE as “a patient room that is […] intended to protect a high-risk immuno-compromised patient from human and environmental airborne pathogens.”

- Airborne Infection Isolation (AII):

The isolation of patients infected with severe airborne diseases. This paper will refer to “AII” Rooms” as the room that provides this isolation.

- Facilities Guideline Institute (FGI):

An organization that develops guidelines for the design and construction of hospitals and other heath care facilities.

1. What is room pressurization?

Room pressurization is a ventilation method that allows for control of the migration of airborne contaminants between rooms. This is accomplished by controlling the amount of air supplied, returned, or exhausted on a room by room basis.

Room pressurization is leveraged in stairwell systems to control smoke during fire events, in restaurants to help control food odors, as well as in hospitals to inhibit the transmission of airborne diseases. This white paper will focus on medical applications of room pressurization.

2. How do we determine and set room pressurization?

There are two main factors when it comes to room pressurization, airflow rates and infiltration. As mentioned in a previous paragraph, room pressurization is achieved by controlling supply, return, and exhaust airflow. By supplying more air than is being returned or exhausted, a room becomes positively pressurized to its surroundings. By returning or exhausting more air than is being supplied, the room becomes negatively pressurized to its surroundings. But if we are positively pressurizing a room, where does the excess air go? This is where infiltration and ex-filtration come in to play.

Rooms, and even buildings, are not 100% airtight. There are gaps beneath doors, around window seams, and in other places. If we positively pressurize a room, the excess air ex-filtrates outwards through these nooks and crannies into adjacent spaces due to a difference in pressure. When a room is negatively pressurized, the reverse is true. Air infiltrates into the negatively pressurized room from adjacent rooms. This is what allows us to control the migration of contaminants.

ASHRAE 170 defines the minimum pressure gradient be tween pressurized spaces to be a minimum of 0.01 in. wc. This pressure gradient is measured using pressure transducers, which are required to be maintained and checked at intervals specified in the FGI Guidelines.

3. What types of rooms require pressurization?

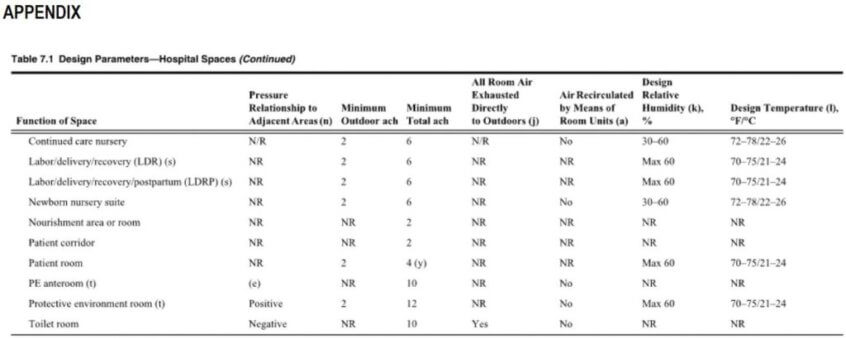

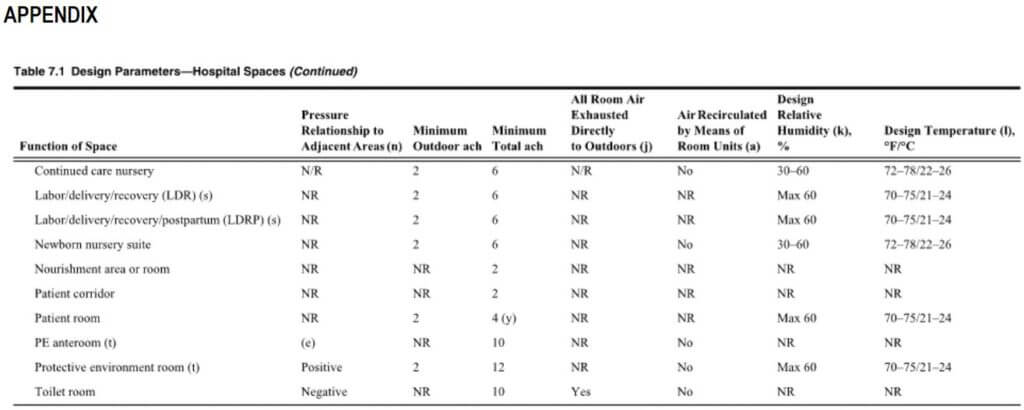

ASHRAE 170 Table 7-1 (see Appendix) outlines room pressure requirements for different medical room types. The pressurization requirements work to minimize the spread of airborne contaminants between rooms. Protective environment rooms are required to be positively pressurized to keep airborne contaminants out of rooms housing patients with weakened immune systems. On the other hand, Airborne Infection Isolation rooms, which house patients with severely contagious diseases, are required to be negatively pressurized to prevent the spread of these diseases to other people in the hospital. Refer to ASHRAE 170 Table 7-1 when questioning room pressurization requirements. An example of how to use Table 7-1 is shown in the appendix.

Above is a sample of ASHRAE 170 Table 7.1. When using this table, first, identify the type of room you are working with. This example will use a protective environment room. You will want to look to determine the pressure relationship required by code for this space. For a protective environment room, a positive pressure relationship is required. The next columns outline required air change rates, expressed in ACH (air changes per hour).

CFM can be obtained from ACH by multiplying the volume of the room in question by the required air change rate found in the table and dividing that value by 60. Both outdoor air change rates and total air change rates are specified in the table. For rooms under positive pressure, your total air changes per hour is dictated by your supply air. For rooms under negative pressure, your total air changes per hour is dictated by exhaust air. A 10% difference between supply and return/exhaust is a good rule of thumb for maintaining proper pressurization in a room.

Have a question for our experts? Leave your comment below and check out our website for more information.